650c versus 700c wheels - Are smaller wheels slower?

Dan

January, 2010

"Why do you use smaller wheels on the smaller size bicycles?"

Related Articles

Trail Mix for the Petite Cyclist

Big Fast Wheels

Are Smaller Wheels Slower?

Small Problem, Big Compromise

A short answer to that question is "because we are willing to go to the trouble to make our bicycles fit our customers perfectly every time". We don't want you to compromise when it comes to fit, comfort and control. That being said, there's a lot of mis-information out there on this subject (and I do mean a $%^# of a lot!), which requires a long answer as I believe education is the best way to inform and maybe help you, the smaller rider, to set aside the blather that's out there regarding this issue.

Trail Mix for the Petite Cyclist

Big Fast Wheels

Are Smaller Wheels Slower?

Small Problem, Big Compromise

So, before I give you the long answer to that question (which I promise I will), let me address the mis-information that I'm sure you've heard (or will hear) repeated in bike shops and even some magazine articles around the United States.

Is a vehicle slower because the wheels are Smaller?

Is a Porsche slower than a dump truck?

The dump truck has bigger wheels and a more powerful engine, but it's the slower of the two right? The wheel size obviously has nothing to do with the top speed. If it did, we would see huge wheels on race cars. Now, some of you may be convinced already, but for those who need more bicycle specific evidence, please continue.

Push, Push, Push

In recent years, manufacturers have been pushing 700c wheels even on their smaller bikes. This has led some to assume that 700c wheels may be faster or better because they are bigger. Some shops even tell customers "650c wheels are slower" to scare them into purchasing a bicycle that they stock (nothing scares a cyclist like the word 'slow'). As a result, I find myself explaining 700c vs. 650c wheels several times per month. After just completing a series of emails with a 5' tall woman who was unhappy with a 700c bike that she had purchased (not from us), I decided that it was time for a basic article on the subject.

Friction, Bricks, and Rotational Mass

On our smaller sized bicycles, we offer 650c size wheels as opposed to 700c, although both are just as fast. I realize that by obsessing on minutia, one will determine that a 650c wheel has to turn a little faster than a 700c to go the same speed. This results in more friction in the bearings. But, by applying the same obsessive, compulsive approach to the weight of the wheels, any increased friction of the bearings is easily negated by the fact that there is less tube, tire, spoke length and rim material to get turning in the first place. This results in less rotational weight. Rotational weight is the 'evil' that everyone with any size of wheel is trying to get rid of. This is because of rotational mass. Imagine a brick tied to the end of a string. Pretty easy to hold up right? Now swing the brick around in a circle. It feels much heavier. If the brick is lighter and the string is shorter, then it's easier to spin. Rotational weight of a wheel is magnified in this same way. As a wheel starts to spin, all of the weight out at the end of the spokes is 'the brick'. Less rim, spoke, tire, tube, etc. equates to a 'lighter brick' to spin, and a smaller diameter equates to a shorter string. A lighter wheel is much easier to spin up to speed than a heavier one.

Need more scientific evidence than a 'brick on a string'? Here's a scientific article detailing the effect of weight and size on the rotational mass of a spinning object.

"C'mon Dan! That article was way techo-geek speak!" "How about some easy proof that everyone can understand?"

How about Ice Skating? Here's a quick article of how an ice skater speeds up their spin.

Gearing

Ah Ha! But what about the fact that one revolution of your cranks results in less forward motion if your wheels are smaller? I've had people ask me that quite a bit too. That's just a function of the gear ratio that's selected for your style of riding and your strength. It's the same on a car. A Porsche with small wheels is geared higher than a dump truck. The record setting bicycles pictured below are geared WAY higher than any bicycle that you or I will ride. Wheel size is on of the determining factors in specifying the gearing for your bicycle, not the speed of your bicycle.

Faster speed is not the reason for using 700c wheels as a standard. For instance, if a larger wheel was faster, then why not return to the 27" wheel standard of the 1970's? This is a bigger wheel than a 700c, yet no company (or magazine for that matter) has embraced it as faster than a 700c. I think that any shop telling customers "27" wheels are 'faster'" would be laughed out of town. Yet, this is exactly the same thing as saying "700c wheels are faster than 650c".

When someone in the industry (people in the industry should know better) tells a smaller rider "small wheels are slower", what I hear them saying is "riding with knee pain, discomfort in your shoulders, neck, back and numbness in your hands on a bicycle that's harder to control can make you ride faster." This doesn't sound like good advice to me. Especially when there's so much proof that their "smaller=slower" claim is completely false.

Myth Busting:

Obviously if bigger wheels were faster, one would expect to find bigger wheels, not smaller wheels, on record setting bicycles that are ridden at speeds of over 150mph. Yet, these guys chose really small wheels. Maybe they didn't talk to the guy at the shop

Don't believe me? Ask these guys and gals

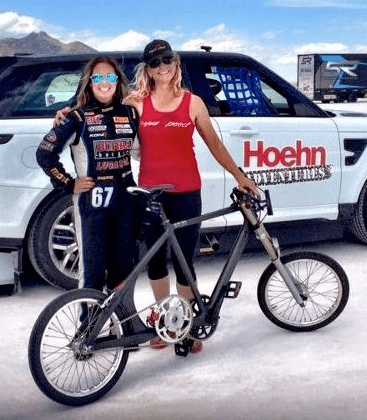

Denise Mueller sets the Women's world record at 147 mph in 2016

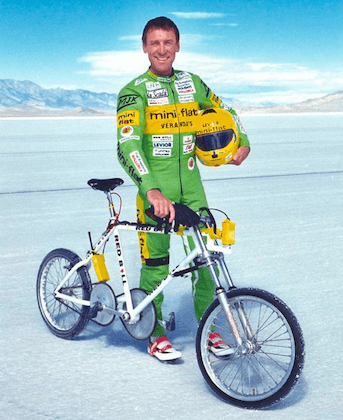

Fred Rompelberg sets the current men's record of 167 mph in 1995

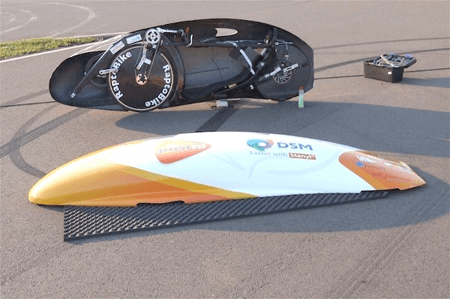

In September 2016, Todd Reichert rode the Aerovelo bicycle with no motorpace to 89.6 mph. He was also not towed to any speed. You may not be able so see from the pictures, but this bicycle uses 650c (26") wheels. The same size we use on our race bikes for petite riders. So other shops and magazines....Quit lying to your customers and readers!

John Howard sets the world record at 152.2 mph in 1985

Al Abbott sets the world record riding past 138 mph in 1973

If you're looking for a bicycle, and someone tells you smaller wheels are slower, they are either mis-informed, or they don't have your best interests at heart.

Still not convinced? email me, I've got plenty of testimonials and other articles on the subject. I've got no incentive to push either wheel size, and I own bicycles with both wheel sizes. I just hate to see people receive bad information and get a bike that doesn't control well and isn't comfortable.

The Real Cause of "Slow"

One thing that everyone can agree on is that discomfort, pain, and low confidence for controlling a bicycle will always result in slower riding. This isn't even up for debate. Feeling comfortable and in control is the best way to speed up your ride. When the industry (or bike shop) is telling smaller riders "bigger wheels are faster", I think what they mean to say is "make my job easier by compromising the comfort, fit, and confidence that taller riders experience."

The real truth is that Comfort and Confidence = Better Performance and Faster Speed.

Why then would the industry try to push one wheel size?

Answer: Profit -

The reason the industry wants to push 700c is that it's easier to spec bikes if all your bikes use the same size of wheel. When you slip a 650c in the mix for your smaller bikes, for instance, now instead of 1,000 of the same 700c forks, you're ordering maybe 800, and then 200 of the 650c forks. This same thing holds true for rims, tubes, spokes, carbon wheels, rim strips and tires. For high tech racing bikes, wheels are carbon and require expensive molds to make. It could cost an extra $30,000 just to make molds for 2 wheel sizes. In effect, you've just raised your cost on the entire run of 1,000 bikes because you've increased the numbers of individual SKU's as they are called in mass production. If a big bike company orders their bikes in 10,000 unit quantities for each model from a Taiwan or Chinese manufacturer, their costs could increase maybe 20%~25% if they started trying to offer the type of flexibility that a small company like us can give you. Building one bike at a time has its advantages.

By not offering that choice to smaller riders, they put their dealers in the awkward position of having to sell against those of us who do offer that same choice. We don't purchase expensive advertising in magazines, and the big guys do. This gives them some power to influence the opinions of those enthusiasts who subscribe to those magazines including many who work in bike shops.

Giving In:

Many companies just give in to the pressure, and quit offering good fitting smaller bikes rather than go to the trouble to innovate. As you can see, it would be much easier for us too if we just did what they do, and pretend there are no better options for you. Instead, we spend a lot of time and energy to get forks (carbon as well as steel), rims, spokes and tires for our smaller sized customers bikes. We think they deserve the same comfort and control as the 6' tall guys.

Why do Bigger wheels cause a problem on a smaller Bike?

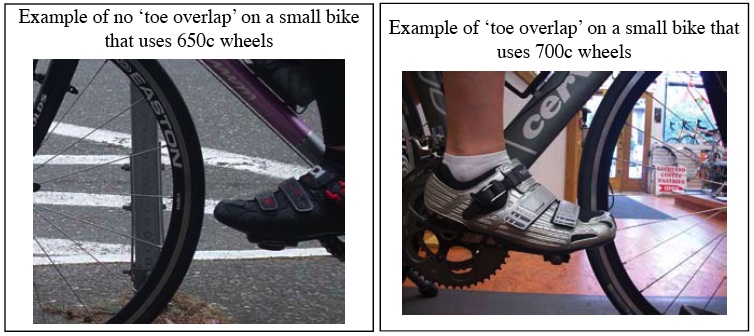

It all boils down to something called Toe Overlap:

If your front wheel hits your foot when you turn, this is called 'toe overlap'. The smaller a frame becomes, the closer the front wheel gets to the rider's foot. A small amount (maybe 1cm or so) of 'toe overlap' can be common on modern bikes, but more than 1cm can be quite a nuisance, especially if the rider wants to use fenders.

Good Design

The main reason we use a smaller wheel on a smaller bike is good design. A smaller wheel allows us to produce a shorter reach frame with the proper head tube angle for good control while at the same time minimizing any, if not all, toe overlap. Using a 700c wheel on a bike with an effective top tube of less than 53cm requires design gymnastics (or in some cases, cheating a little) to keep this from happening. Design gymnastics result in improperly fitted bikes, or bikes that handle poorly.

Note:The bike on the right with the extreme toe overlap was brought into our shop to be looked over after a crash. The rider said that they had swerved to miss a car door, and crashed un-explainably. I can explain the mystery crash. It's obvious to anyone that a sudden maneuver on this bike is dangerous.

The days of yesteryear:

Years ago (1990 and before), we built lots of small bikes with 700c wheels and steel forks. We could change the head tube angle to a more 'slack' degree to move the wheel further out in front of the rider and then build the fork with more 'rake' to accommodate proper handling. The more 'slack' the head tube angle, the more 'rake' is required in the fork to maintain the appropriate 'trail' number. The added rake moved the wheel out even further.

Now that carbon forks are the norm, they must be purchased from manufacturers who do not offer products with rakes required to accommodate really slack head tube angles. If we could custom make carbon forks one at a time, the way we used to make steel forks, then we could pull this off, and our jobs would be easier.

The things I've seen:

Smaller bikes with 700c wheels and modern carbon forks have been made by many manufacturers, and I've probably seen them all in the repair shop. The compromises used are many. Here's a list of the compromised designs I've seen:

1.) Completely ignore proportions:

Some manufacturers don't even pretend. They simply make the small frames with a 54cm top tube, just like their bigger frames. So the reach to the handlebars for a 5' tall rider is the same as the 5'8" rider.

I actually appreciate this approach simply because it doesn't pretend to be something it's not.

This compromise will provide the proper stand-over height, but a shorter rider's reach to the bars will be a long trip and a very uncomfortable ride (sore neck, back, arms, shoulders, etc.). Many shorter riders know what I'm talking about as they've never been offered a proper fitting bicycle for most of their life.

2.) Sacrificed performance:

If the head tube angle is made very slack, say 69 degrees or less, that will usually be enough to get the 700c wheel out of the way of the foot of most people who need a top tube of less than 53cm, even with a modern carbon fork. "Why not just do that?" you ask? Well, it gets really technical to explain, but 'trail' is the reason. In short, if a bike has a very slack head tube angle, but not enough rake in the fork, the steering is affected in a very negative way. I actually rode an expensive custom titanium bike made this way a few years back and was shocked at how poorly it handled. I wouldn't have been doing the 'look ma, no hands' trick unless it was followed by the 'look ma, no teeth' trick.

This compromise will result in a bike that handles like a poorly designed chopper. The bike will be hard to control in tight corners, and just not as much fun as it should be.

3.) Resort to Trickery:

Here's a tricky one. If a bike has a modern carbon fork, a 72 degree head tube angle, a top tube length of 51cm, no toe overlap, and 700c wheels, has the company found the magic formula? No. They have artificially shortened the top tube by making the seat tube angle really steep. What this means for the rider is that the seat will have to be pushed all the way back on the rails in order to get the knees in the right pedaling position (unless they like really sore knees). Once the seat is pushed back on the rails to accommodate for thigh length, the reach to the bars becomes the same as if the top tube were 54cm, and the rider is even more un-comfortable than in 'compromise number 1'.

Result - Same as compromise 1 with a little knee pain thrown in as an extra treat. Discomfort and pain always results in slower riding, and that's one thing that everyone can agree on.

4.) Embrace toe-overlap:

Some manufacturers (like the one pictured above) simply sell their smaller bikes with the same head and seat tube angles as they use on their bigger bikes. Then they just put on the big wheels and hope the rider is careful when they turn corners. This has been an option that I've had customers choose, but then return the bike after deciding they didn't like it. As I said before, some folks are fine with it, but for the top tube lengths of 52cm or less, I've rarely had a customer happy with an extreme amount of toe overlap. Remember, most manufacturers will not take the bike back for a refund.

Result - The rider has to be extremely careful not to pedal while cornering. Sudden corrections or swerves will often result in a 'mystery crash' like the one referred to in the photo depiction above. Lost confidence because of the danger will result in slower riding (there's the 'slow' word again).

5.) Use proportional wheels:

Here's an idea....why not go to the extra expense and use a little smaller wheel on the bikes that are smaller? This is the method that companies use when they are trying to provide the best fitting bikes without compromising safety or good performance. It costs a lot more for the manufacturer, and requires a commitment to, and understanding of their customer's needs. We can't pretend that there's no difference, and again, we would love to return to the days of one size wheel for all the bikes, but the fact is that wouldn't be the best for our customers.

We aim to please!

What ever your wishes, we're happy to build a bike for you. If you need a smaller bike, and you really want 700c wheels, we're happy to build that, we just want you to be able to make an educated decision before you spend the money. We make bikes like this several times each year. Most of these customers are willing to accept either toe overlap, or a steel fork to enable us to provide them with good design and no toe overlap. Suffice to say, that there is a method to our madness!