Do you want a Forever Bike?

DanNovember, 2012

What you don't know can cost you thousands

In our repair shop, we see several expensive bikes each year rendered useless! When I say expensive, I mean bikes that sold new for over $5,000. Sometimes they remain in the repair shop waiting for parts for most of the riding season, and sometimes they are off the road forever. That seems unacceptable to me for bikes this expensive, and less than five years old. It's amazing to me that the customers were unaware that the bike they purchased for such a large sum of money was designed to become obsolete after a few years. This is due to the use of proprietary parts, or parts that don't comply with ISO standards.

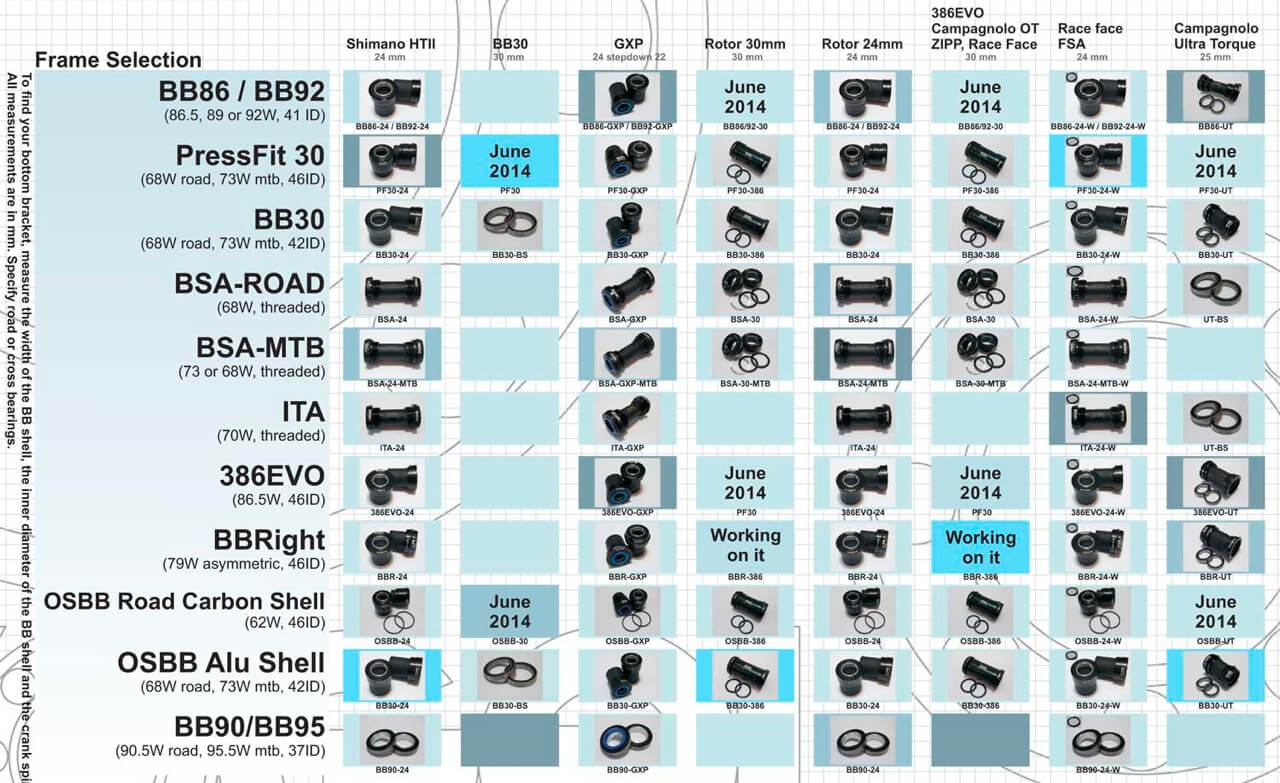

Part standards that are non-ISO compliant are phony 'standards' that are really just new designs issued by companies wanting to say that their bikes use standard parts. Examples of phony standards are things like BB30 bottom brackets, or integrated head set standards. The difference between proprietary parts and these phony 'standard' parts is that they allow anyone to use the new 'standard' if they want to....so....somehow that makes it a standard. This is just another way to build planned obsolescence into an expensive bicycle.

Most people think that if they are paying thousands of dollars for a bicycle, it will last more than a few years. They are also under the impression that they can have the bike repaired in just about any bike shop. For most high-end bikes manufactured today, this is not true.

The Real Standards: For those of you who want to buy an expensive bike that will last forever, this article is a must read. ISO, or International Standards Organization, is a term that you need to familiarize yourself with before laying out the big dollars. I've written an article about ISO called Chaos that can be read here. If you want a bike that can be repaired by any bike shop around the world, for as long as you own it, then there are areas of the bike that need to comply with ISO standards. Otherwise, it will become obsolete and may do so in just a year or two.

First, one real life example of what I'm talking about:

Can you imagine purchasing a $5,000+ bike and then just a few years later, having to purchase a new frame to replace it? Not because of a wreck, but because the frame broke at the bottom bracket under normal use. This is an actual case that happened last summer in our shop.

A high end carbon fiber frame was brought in because the customer had shifted into the spokes and broke the derailleur hanger off of the bike. He was told by the manufacturer that his warranty would be void if he had it repaired. The local shop where he bought the bike told him he was S.O.L. Well, he had to have it repaired in order to ride the bike, so he hired us to machine an aluminum hanger and attach it to the frame (see picture to the right).

A few months later, the frame broke at the seat tube, completely unrelated to the new derailleur hanger. The break was at the point where the seat tube meets the bottom bracket 18 inches away from the derailleur hanger. The manufacturer said 'no warranty because the frame has been modified'. This is a common theme among big manufacturers these days. Really, these expensive carbon bikes are designed to last about 5 years. The trend is to design an expensive frame that is not repairable in any way, and then deny warranty because of some technicality. Can you believe that exposure to sunlight can void your warranty on some carbon frames?

The customer in this story now owns a Rodriguez lifetime bike that complies with ISO standards. He brought the carbon fiber frame in for us to cut to pieces and dispose of in our dumpster. He loves his new Rodriguez S3 frame, and says it rides even better than the other bike ever did. Another pleasant surprise was that his S3 steel Rodriguez is also lighter than his carbon bike!

I'm trying very hard to get the word out about proprietary parts, and what they mean to you as a cyclist. The noise of cycling magazines filled with 'experts' telling people the benefits of XXXX company and their new design seems to drown out common sense.

So why are companies using non-standard parts?

I can't read their minds, but I can think of several reasons that manufacturers can benefit by deviating from ISO standards.

- Control of warranty costs

Let's say that a manufacturer wants to advertise that they offer a 'lifetime' warranty on their frame, but they really don't intend for that frame to be on the road in 30 years. Simply design the frame to work only with a proprietary fork, or headset, or bottom bracket, etc. After 4 or 5 years, they just stop making that proprietary part and the 'lifetime' frame warranty is useless. They're not going to give you a new frame because your head set wore out, or your fork broke right? Don't think they would do that? Read the example above. They'll look for any technicality they can to 'opt' out of the warranty. I think this is why some manufacturers that offer lifetime frame warranties only offer 5 year warranties on their proprietary forks. - Better design

Let's give them the benefit of the doubt and say that they've come up with a design that is better. I'm sure there are improved designs out there, but the fact remains that unless the part is compliant to ISO standards, you're taking a risk. I've found that the "better mouse trap" usually has a big following for a few years, gets some great write-ups in magazines, and then it's off the market again. It's really interesting to read Bicycling magazines from the 1970's and see all of the new designs that are going to revolutionize the industry, and then try and find one of those designs manufactured now. Unless you want to pay to be their product test subject, I suggest sticking with the 30+ year old standards. - Trickery in advertising

Let's say a company wants to advertise an honest frame weight that's lighter than everyone else's frame. It's possible to make a frame even lighter with the use of proprietary or non-ISO compliant parts. The funny thing is, when the proprietary parts are installed, then the overall weight of the bike is actually heavier than a light bike with the ISO compliant parts. Don't be fooled on that one. A frame weight for a bike using proprietary head set, bottom bracket, or forks is going to result in no weight savings when the bike is built up completely. All you end up with is an expensive bike that is heavier, and will not last forever. - Profit for their dealers

This one's a no brainer right? If there's no competition for the proprietary parts, then the profit margins can be really high. If your bike won't work without a bottom bracket, and the only one you can buy for your bike is the one made for your bike, and it's only available at the dealer......you get the point. This arithmetic is heading in one direction and that is higher, higher, and higher prices. Ouch! Not the direction that most of our customers want to go. - They don't love their customers....

...OK, maybe they do love their customers, I don't know. What I do know is that they're not doing their customers any favors by selling them non-standard parts. I've always said that when you purchase a bicycle, you're purchasing a relationship with the dealer and the manufacturer of that bicycle. If you want that relationship to be a pleasant one that lasts, make sure that they share your philosophy and expectations you have before you spend the money.

Avoid the

chaos of non-ISO compliant parts! At Rodriguez Bicycles, we go out of our way to make life easy for our customers, and build them a bicycle that will last them a lifetime. We use ISO compliant parts so that you'll be able to get your Rodriguez repaired at any shop just about anywhere. We love

our customers, and they love their Rodriguez Bikes!

Avoid the

chaos of non-ISO compliant parts! At Rodriguez Bicycles, we go out of our way to make life easy for our customers, and build them a bicycle that will last them a lifetime. We use ISO compliant parts so that you'll be able to get your Rodriguez repaired at any shop just about anywhere. We love

our customers, and they love their Rodriguez Bikes!